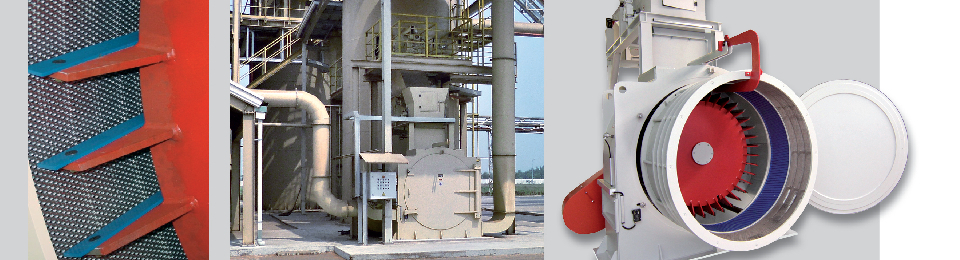

MAIER Impact Mill - MPM

Application

- Surface layer production in particle board industry

- Preparation of filling and insulation material

- Preparation of fuel for thermal utilization

- WPC/WFC

- Animal food and bedding

Description

The MAIER Impact Mill MPM enables the continuous processing of soft to medium-hard materials into cubic fine flakes or wooden powder.

After passing the vibration conveyor, the permanent magnet drum and the Heavy Particle Separator the material is fed from the rear side into the grinding chamber, where it is milled between the rotor beater ledges and the grinding track.

The material is finally reduced and calibrated by the integrated special fine hole screen.

Customer benefits

- Wide range of input materials like pre-sized wood, annual plants, grain, seeds and spices

- Adjustable degree of fineness

- Fast screen exchange without removing the complete grinding ring

- Low maintenance and service-friendly

- Onfloor or pit installation; pneumatic product discharge laterally or downwards possible

Technical features

- Grinding track segments and their configuration adaptable to the input material

- Wear-resistant, clamped and easily exchangeable grinding track segments

- Special fine hole screens with different mesh-sizes applicable

- Divided beater ledges for selective exchange of the worn parts

- Maintenance opening in casing for easy exchange of the rotor beater ledges